A CAT6A patch panel is a type of patch panel used for structured cabling systems that is designed to support the CAT6A standard for Ethernet networking. CAT6A (Category 6A) is a higher-performance version of the standard CAT6 (Category 6) cable and is capable of higher speeds and greater bandwidth.

A patch panel is a device that allows for the organization and management of multiple cables by providing a central location for connecting and disconnecting cables. The CAT6A patch panel typically includes a series of ports, or jacks, that are used to connect individual cables to the panel. These jacks are typically labeled for easy identification and organization of the cables.

CAT6A patch panels are designed to be used in data centers, server rooms, and other high-performance networking environments where high-speed data transfer and low crosstalk are critical. It also supports 10Gigabit Ethernet standard, which makes it suitable for high bandwidth applications.

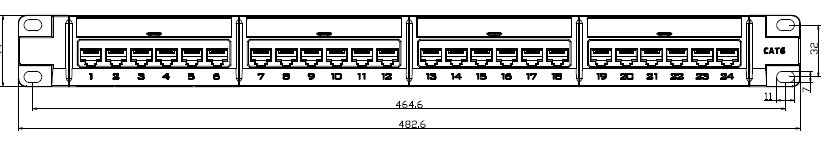

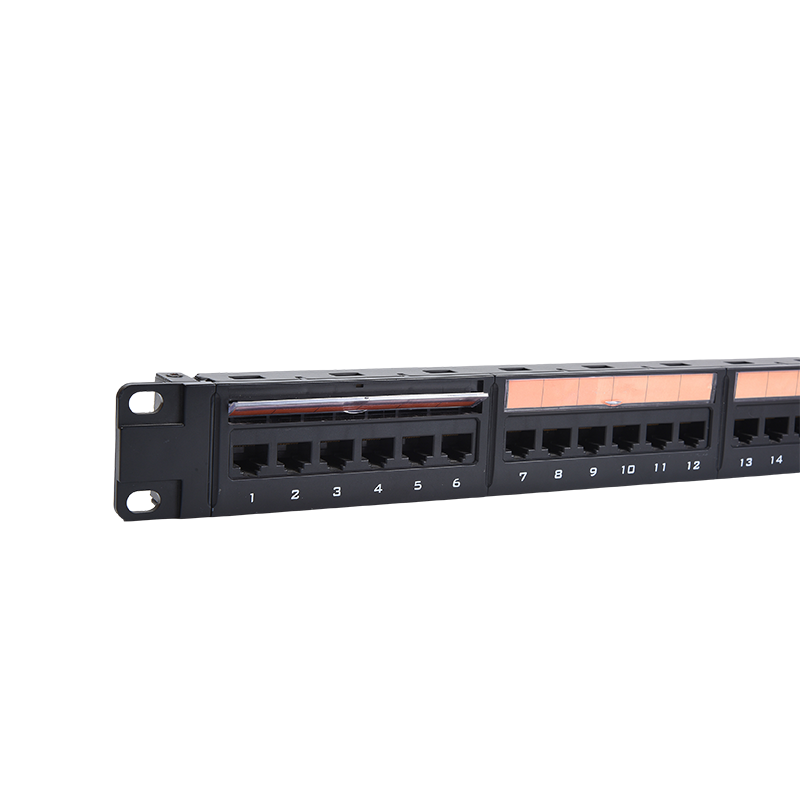

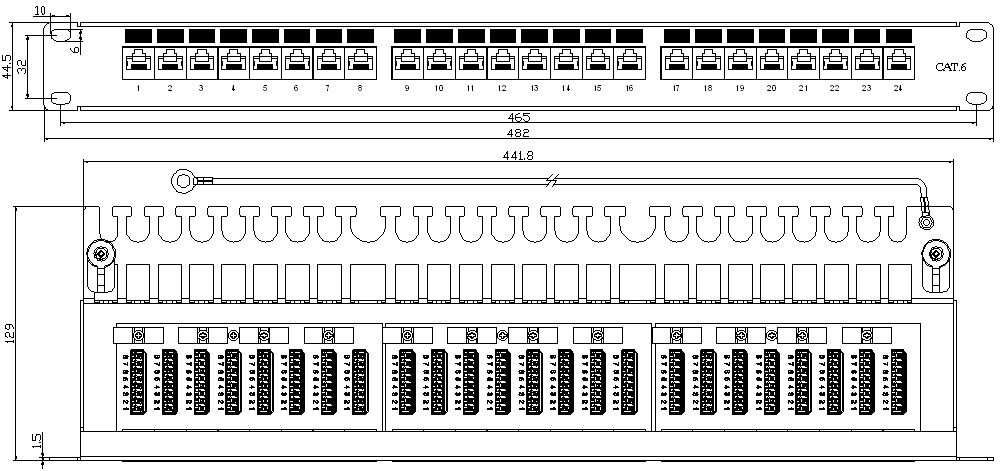

1.19" rack mount standard, sturdy, easy-to-install design, greatly improving work efficiency; compatible with 19" equipment racks, cabinets and wall mounts.

2. The front of the 24 ports are marked with labels for convenient port identification; the back has a cable manager, which can effectively guide the cable to the termination point.

3. Connection method: RJ45 jack with jumper, IDC terminated with horizontal wiring. The contact pin contact adopts high and low dislocation technology, which effectively reduces the near-end crosstalk value. 360-degree all-round shielding shell design to prevent EMC electromagnetic interference. The rear cover of the shielding cover is fixed with a non-screw design, which is convenient and quick to install.

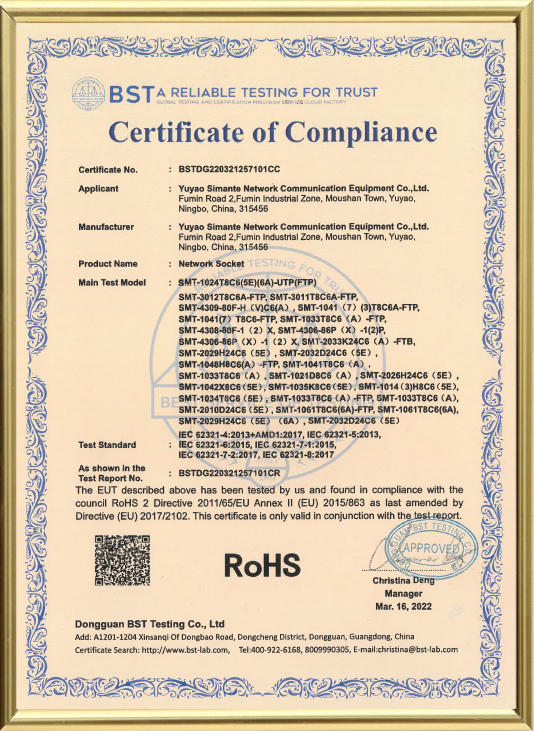

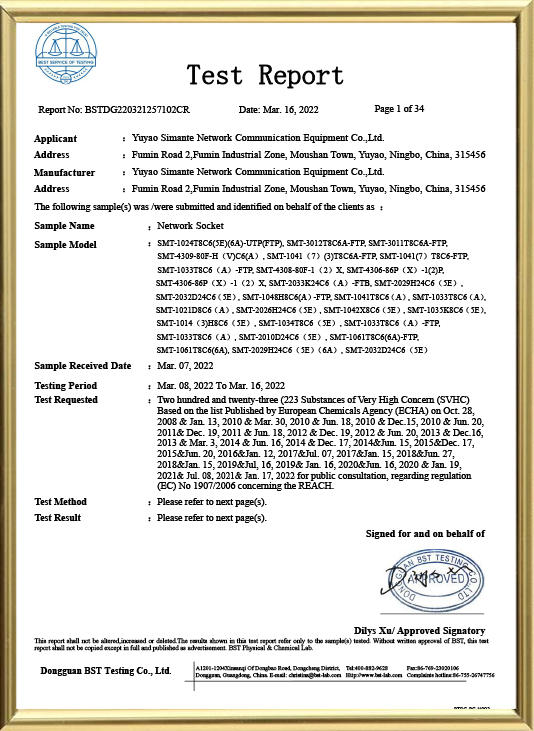

4. Environmental requirements: meet ROHS standards.

5. Material introduction: This patch panel product is used to connect the horizontal wiring and working area wiring on the same floor of the building, and is mainly used for the conversion connection of wiring equipment and terminal equipment or adapters. Product mating and mating cables are copper-axle twisted pair cables and copper-axle jumpers.

6. Inter-matching relationship: use with connectors of the same standard series

7. Applicable standard: General specification: YD/T 926.1-2009

Sub-standard: YD/T 926.3-2009

8. Technical parameters:

Electrical Characteristics:

A. Frequency range: 1~250MHz

B. Working voltage: 125 V

C. Withstand voltage: DC1000V (AC750V) 1min without breakdown and arcing phenomenon

D. Near-end crosstalk attenuation: ≥3dB

E. Insulation resistance: initial value ≥ 100MΩ

After constant damp heat test ≥100MΩ

Mechanical properties:

A. Insertion force and pull-out force: the insertion force is not more than 20N, and the pull-out force is not less than 20N

B. Effect of connector connection device: 50N 60±5s

C. IDC terminal is clamped to 23~26AWG twisted pair

Durability:

A. The number of times the plug and socket are inserted: 750 times

B. Number of wire terminations: 250 times

9. Material and surface treatment:

A. Metal material:

Bracket: cold rolled steel sprayed with plastic

Gold Needle: Phosphor Bronze Gold Plated

IDC card wire terminal: Phosphor bronze nickel plated

B. Non-metallic materials:

Plastic: PC polycarbonate, PBT

C. Thickness of gold-plated layer: 3~50U gold-plated

D. PCB material: FR4

10. Environmental performance: Temperature: -25~+70℃ Humidity: ≤85% (temperature 85℃±3℃)

Salt spray test:

A. The pH value of the salt solution before atomization is between 6.5 and 7.2 (35±2℃);

B. The salt solution is prepared with sodium chloride (chemically pure, analytically pure) and distilled or deionized water.

Its concentration is (5±0.1)% (mass percentage);

C. Continuous atomization is adopted, and the recommended duration is 48h;

D. When atomizing, it is necessary to prevent impurities such as oil and dust and the temperature and humidity of the jet air from affecting the work.

conditions for the space.

11. Outline drawing and maximum size customized.

12. Packaging and storage: The product is put into a special blister bag, and then put into a cardboard box, and the product accessories are placed at the same time, and a label indicating the product model and quantity is affixed on the upper left corner of the front of the carton , and put it in the carton. The packaged products should be stored in a warehouse where the ambient temperature is -5℃~+30℃, the relative humidity is not more than 70%, and there is no acid, alkali and other corrosive gases in the surrounding air, and the storage period is three years.

Regular packing quantity: 10 boxes per box, 1 per box, 10 per box.

13. Note: product use mark: customer specified packaging.

Español

Español عربى

عربى