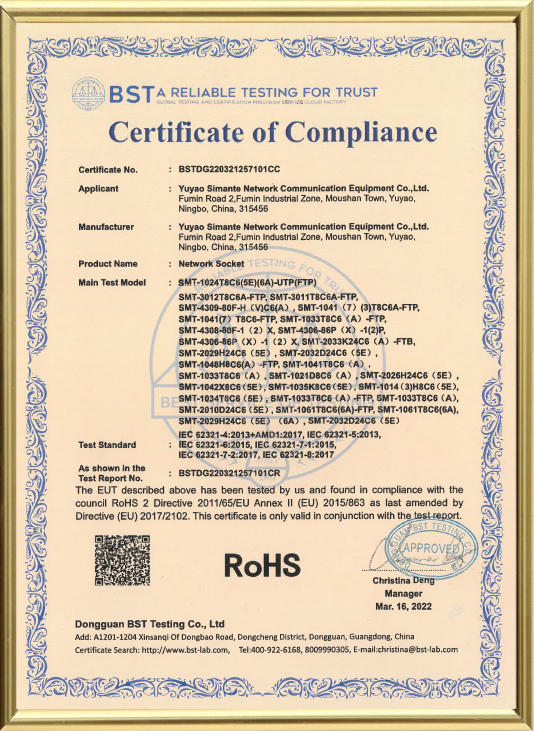

1. Environmental requirements: meet ROHS standards.

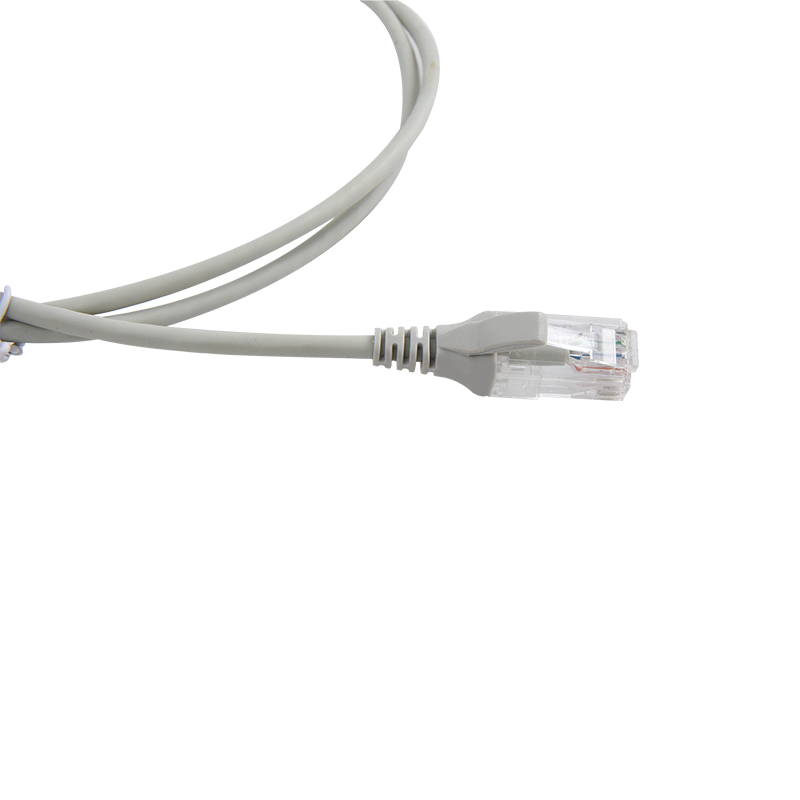

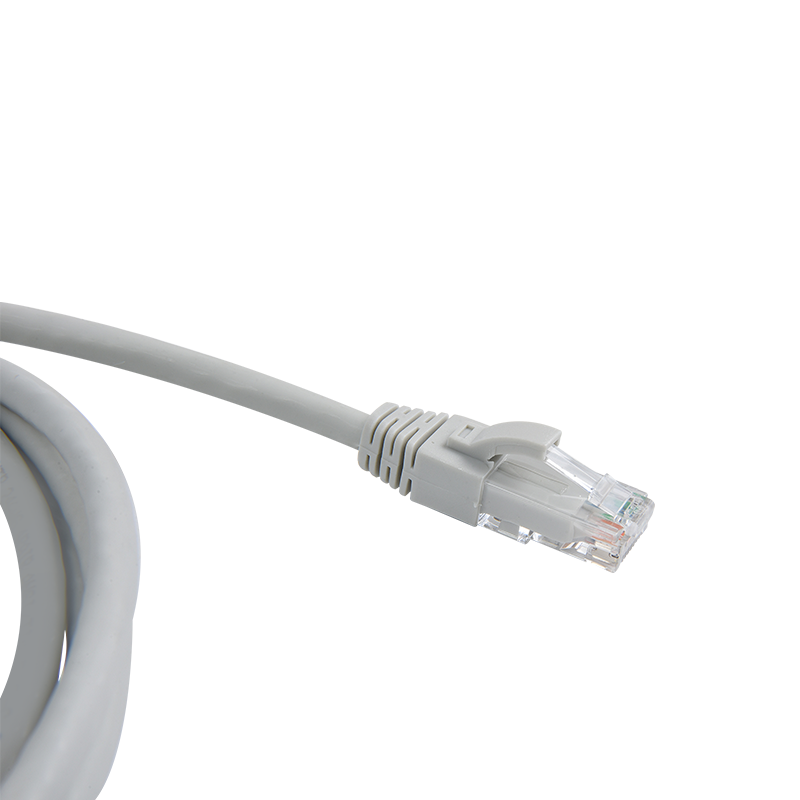

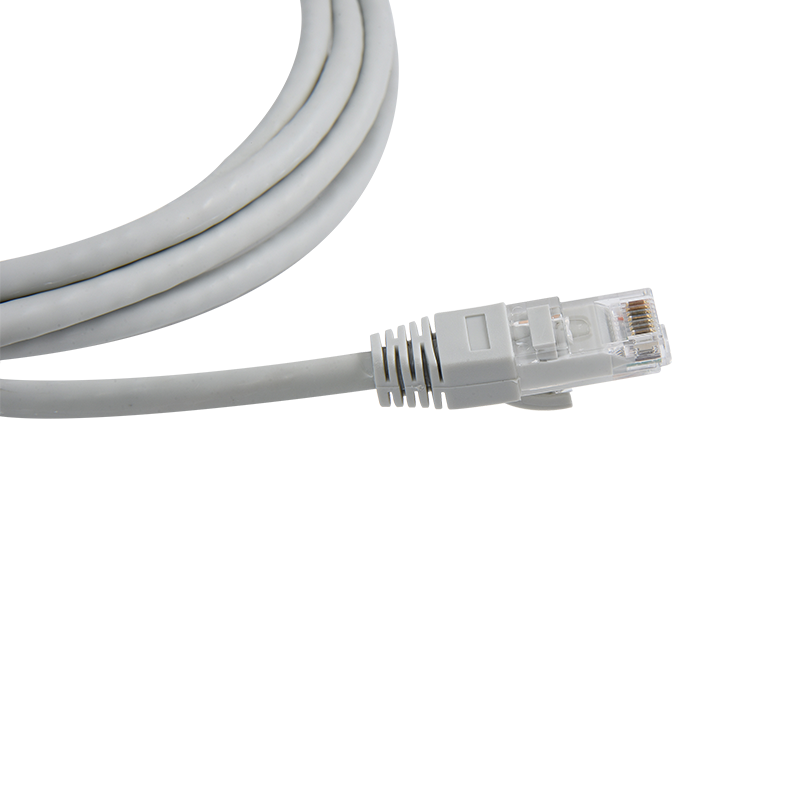

2. Material introduction: This jumper product is used to connect the horizontal wiring and work area wiring on the same floor of the building, and is mainly used for wiring equipment and terminal equipment or adapter conversion connection.

3. Inter-matching relationship: use with connectors of the same standard series

4. Applicable standard: ISO/IEC:2002 TIA/EIA 568B

5. Technical parameters:

Electrical Characteristics:

A. Frequency range: 1~500MHz

B. Withstand voltage: DC1000V (AC750V) 1min without breakdown and arcing phenomenon

C. Near-end crosstalk attenuation: ≥2.5dB

D. Insulation resistance: initial value ≥ 100MΩ

After constant damp heat test ≥100MΩ

Mechanical properties:

A. Insertion force and pull-out force: the insertion force is less than 20N, and the pull-out force is less than 20N

B. The tensile strength is greater than 90N

C. The bending radius is greater than: 4D or greater than 8D

Durability:

A. The insertion times of the crystal head and the socket are more than 750 times

6.Material and surface treatment:

A. Metal material:

Crystal head gold piece: brass gold plated

Cable conductor: pure copper (purity greater than 99.99%)

B. Non-metallic materials:

Crystal head plastic: PC polycarbonate

Cable cover: PVC polyvinyl chloride

Insulation layer: high density PE (polyethylene)

C. Thickness of gold-plated layer: FU~50U gold-plated

7. Environmental performance: Temperature: -40~+70℃ Humidity: ≤85% (temperature 85℃±3℃)

Salt spray test:

A. The pH value of the salt solution before atomization is between 6.5 and 7.2 (35±2℃);

B. The salt solution is prepared with sodium chloride (chemically pure, analytically pure) and distilled or deionized water.

Its concentration is (5±0.1)% (mass percentage);

C. Continuous atomization is adopted, 8h-48h according to the thickness of the gold-plated layer;

D. When atomizing, it is necessary to prevent impurities such as oil and dust and the temperature and humidity of the jet air from affecting the work.

conditions for the space.

8. Packaging and storage: The product is put into a packaging bag, sealed and packed in a box, and a label is attached to the upper right corner of the carton. The packaged products should be stored in a warehouse where the ambient temperature is -5℃~+30℃, the relative humidity is not more than 70%, and there is no acid, alkali and other corrosive gases in the surrounding air, and the storage period is three years.

9. Note: Product use mark: customer specified packaging.

Español

Español عربى

عربى