1. The performance conforms to TIA/EIA/ISO standards

2. Connection method: Support enhanced 110 IDC wiring method.

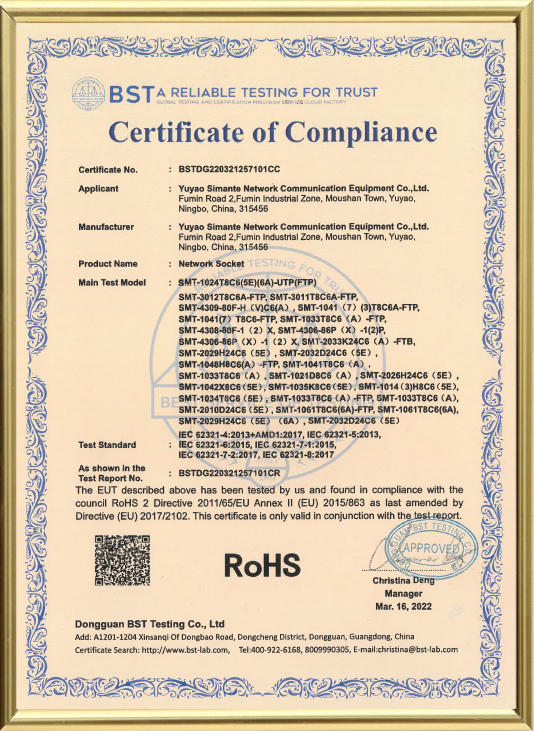

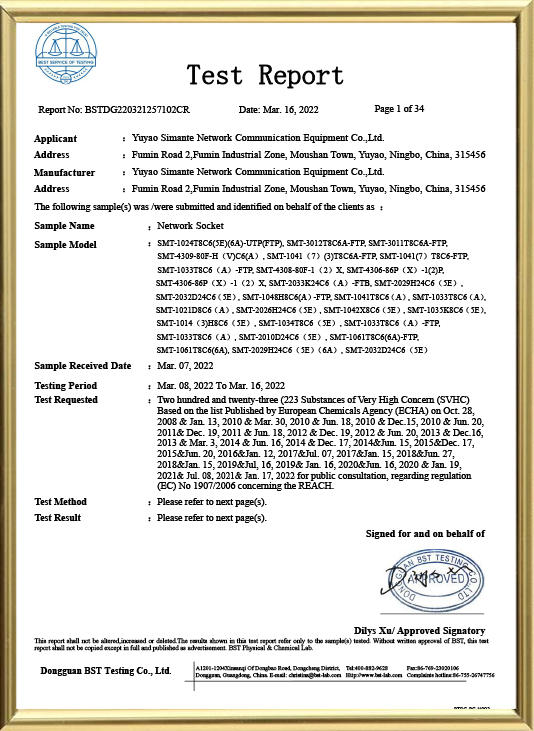

3. Environmental requirements: meet ROHS standards.

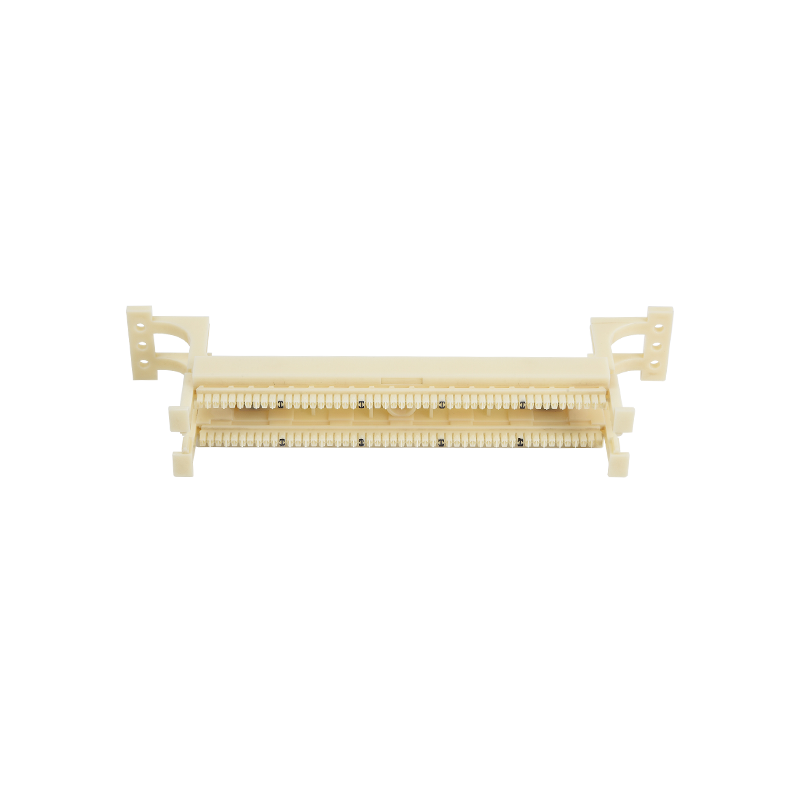

4. Material introduction: The biggest feature of the integrated wiring system is to use the same interface and the same transmission medium to transmit various information on it, and at the same time use the wiring jumper method to flexibly control the application function of each desktop information point. Therefore, the patch panel used for terminating the horizontal twisted pair cables from all desktop information points should use the RJ45 interface patch panel, and for terminating the multi-pair voice cables from the main telephone room, the corresponding pairs of 110 should be used. The patch panel is enough, and the voice connection is realized by jumper connection with the RJ45 port 110 patch panel.

5. Inter-matching relationship: use with connectors of the same standard series

6. Applicable standard: General specification: YD/T 926.1-2009

Sub-standard: YD/T 926.3-2009

7. Technical parameters:

Electrical Characteristics:

A. Withstand voltage: DC1000V (AC750V) 1min without breakdown and arcing phenomenon

B. Insulation resistance: initial value ≥ 1000MΩ

Mechanical properties:

A. IDC terminal is clamped to 23~26AWG twisted pair

Durability:

A. Number of wire terminations: 250 times

8.Material and surface treatment:

A. Metal material:

IDC card wire terminal: Phosphor bronze nickel plated

B. Non-metallic materials:

Plastic: PC polycarbonate

9. Environmental performance: Temperature: -25~+70℃ Humidity: ≤85% (temperature 85℃±3℃)

Salt spray test:

A. The pH value of the salt solution before atomization is between 6.5 and 7.2 (35±2℃);

B. The salt solution is prepared with sodium chloride (chemically pure, analytically pure) and distilled or deionized water.

Its concentration is (5±0.1)% (mass percentage);

C. Continuous atomization is adopted, and the recommended duration is 24h;

D. When atomizing, it is necessary to prevent impurities such as oil and dust and the temperature and humidity of the jet air from affecting the work.

conditions for the space.

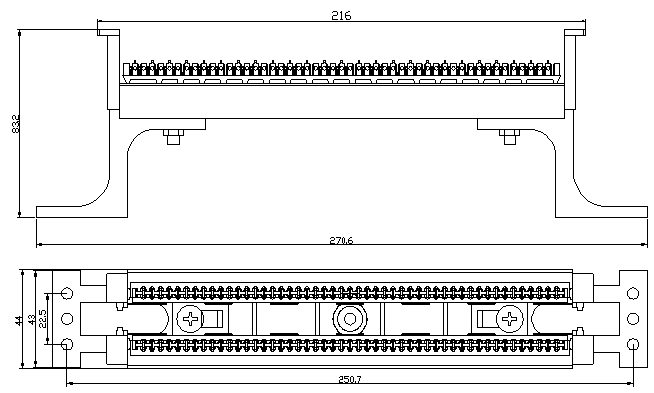

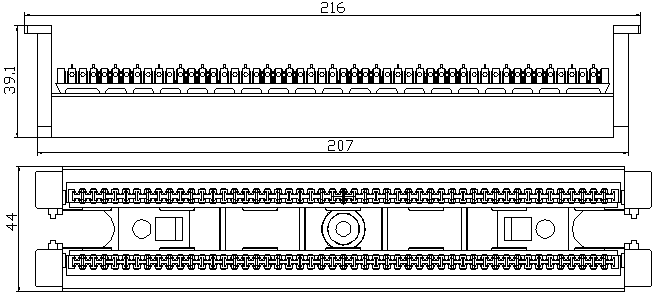

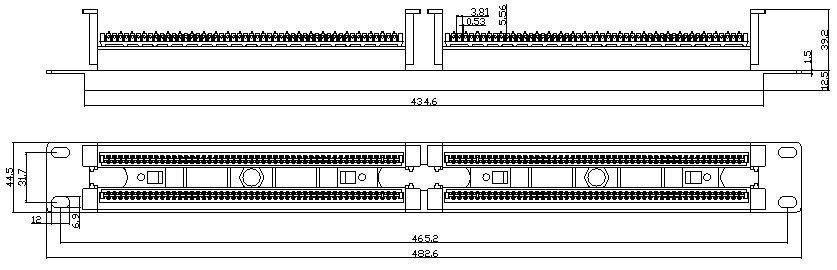

10. Outline drawing and maximum size customized

11. Packaging and storage: The product is put into a special blister bag, and then put into a cardboard box, and product accessories are placed at the same time, and a label indicating the product model and quantity is affixed on the upper left corner of the front of the carton , and put it in the carton. The packaged products should be stored in a warehouse where the ambient temperature is -5℃~+30℃, the relative humidity is not more than 70%, and there is no acid, alkali and other corrosive gases in the surrounding air, and the storage period is three years.

Regular packing quantity: 10 boxes per box, 2 per box, 20 per box.

12. Note: product use mark: customer specified packaging.

Español

Español عربى

عربى