The core purpose of a Faceplate is to provide a safe, clear, and standardized human-machine interface and structural protection for equipment, while improving port management efficiency and overall reliability. Taking embedded Faceplates as an example, their screwless design, modular management, and stable environmental adaptability have led to their widespread application in communication equipment, low-voltage systems, industrial control, and information cabinet scenarios.

Based on the basic information you provided about the Faceplate, the following content will focus on the keyword "Faceplate," systematically analyzing its practical uses and application advantages from aspects such as structural design, usage value, environmental adaptability, and packaging and storage.

Content

- 1 Main Uses of Embedded Faceplates

- 2 The Role of Faceplates in Port Identification and Management

- 3 Faceplate Material Properties and Structural Applications

- 4 Faceplate Environmental Adaptability

- 5 Customizable Uses and Application Flexibility

- 6 Packaging, Storage, and Usage Management of the Faceplate

- 7 Faceplate Marking and Application Instructions

Main Uses of Embedded Faceplates

The core purpose of embedded Faceplates is to achieve centralized display, standardized installation, and convenient maintenance of ports within a limited space.

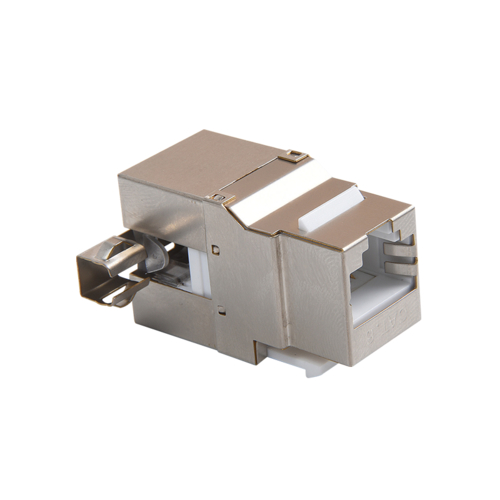

These Faceplates adopt an embedded structural design with no exposed screws, resulting in a flat and aesthetically pleasing finish after installation. They are suitable for network information Faceplates, device interface Faceplates, and control Faceplates. In practical engineering, this structure can improve installation efficiency by approximately 20%–30% while reducing safety hazards caused by loose screws.

The Role of Faceplates in Port Identification and Management

In port-intensive application scenarios, one of the important uses of Faceplates is to improve port identification efficiency. This Faceplate offers greater front identification space and features a removable nameplate for easy port numbering, categorization, and future adjustments. Compared to fixed labeling solutions, the removable nameplate reduces repeated replacement costs by over 50% during network upgrades or equipment modifications.

This makes the Faceplate highly valuable in data centers, low-voltage wiring shafts, and structured cabling systems.

Faceplate Material Properties and Structural Applications

This Faceplate uses high-quality ABS engineering plastic, whose purpose extends beyond aesthetics to provide crucial structural protection.

ABS material possesses excellent impact and shock resistance, is not easily deformed, and effectively protects internal interfaces and modules. According to material performance testing, ABS engineering plastic exhibits an impact strength 2–3 times that of ordinary plastics under normal impact conditions, making it suitable for long-term stable use.

Faceplate Environmental Adaptability

The Faceplate's stability in complex environments directly determines its lifespan and safety.

This Faceplate complies with RoHS standards, meeting environmental and safety requirements. It also supports an operating temperature range of -25℃ to +70℃, making it suitable for indoor server rooms, equipment rooms, and some semi-outdoor environments.

Within this temperature range, the Faceplate maintains structural stability, remaining intact without cracking or deformation, ensuring normal port operation.

Customizable Uses and Application Flexibility

To meet diverse project needs, this Faceplate supports customized outlines and maximum dimensions.

This feature allows the Faceplate to flexibly adapt to different equipment openings, cabinet specifications, and installation standards, making it particularly suitable for customized and non-standard projects. Customizing the Faceplate size effectively reduces on-site secondary processing and improves overall construction efficiency.

Packaging, Storage, and Usage Management of the Faceplate

The Faceplate not only has clear specifications during use but also adheres to standardized requirements for packaging and storage.

The product is packaged in a dedicated blister bag and cardboard box, with product accessories included. A label indicating the product model and quantity is affixed to the upper left corner of the front of the cardboard box for easy warehouse identification and batch management.

Storage environment requirements:

Temperature: -5℃~+30℃

Relative humidity: ≤70%

Free from corrosive gases such as acids and alkalis

Shelf life: Three years

Standard packaging quantities include: 10 boxes, 20 boxes, or 200 boxes per carton, suitable for procurement and transportation of projects of different sizes.

Faceplate Marking and Application Instructions

This Faceplate supports customer-specified packaging and usage markings to meet brand customization and project differentiation needs. This is particularly important in project delivery, after-sales management, and channel distribution, effectively reducing the risk of mismatch and misuse.

The Faceplate serves not only as an installation interface but also as a crucial component of equipment management, environmental adaptability, and engineering specifications. Through its embedded structure, clear labeling, environmentally friendly materials, and standardized packaging, this Faceplate offers significant advantages in practicality, reliability, and engineering adaptability, making it suitable for long-term use in a variety of professional application scenarios.

Español

Español عربى

عربى русский

русский